Doll's Castle has truly mastered the art of crafting high-caliber companions with a keen eye for detail and a heavy emphasis on the end-user experience. Let's take a peek behind the curtain to see how these synthetic sweethearts go from a glimmer in a designer's eye to a tangible work of art.

Production Processes

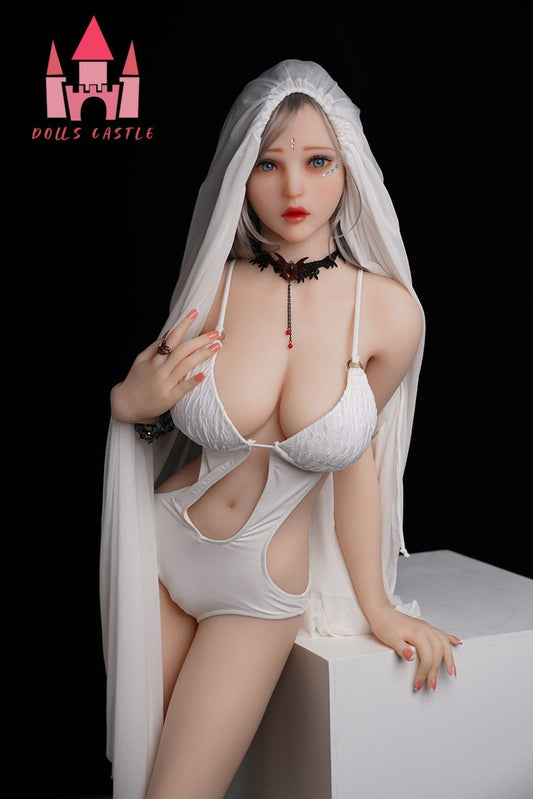

At Doll's Castle, the production journey is nothing short of a meticulous symphony of steps, ensuring each doll is nothing less than perfection. Crafted with a fusion of traditional sculpting and contemporary 3D design, each doll's physique is a masterpiece. The doll's core begins with a high-quality metal skeleton, offering both stability and a delicious range of human-like poses.

Materials matter, and that’s why Doll's Castle dolls are exclusively enveloped in premium TPE (ThermoPlastic Elastomer) or silicone that mimics the softness of human skin to an uncanny degree. The TPE is poured into meticulously crafted molds and then set into the seductive shapes that make each doll a feast for the eyes and the touch.

Quality Control Standards

When it comes to quality control, Doll's Castle doesn’t play around. They employ a formidable triple-checked system that ensures no doll leaves the workspace without being thoroughly vetted for quality and consistency.

- Initial Assessment: Post-production, each doll is initially assessed for any aesthetic imperfections or structural issues.

- Joint and Functionality Tests: Doll's Castle doesn't skimp on mobility, leading each doll through a rigorous series of joint mobility exercises to ensure each movement is as fluid as a Sunday morning yoga class.

- Final Inspection: Before being deemed date-ready, each doll undergoes a final inspection, a thorough head-to-toe once-over to ensure all is in order for ultimate customer satisfaction.

Doll Authority prides itself on offering Doll's Castle's lineup of lovable, lifelike dolls, ensuring that when you choose to bring home one of these beauties, you're in for a top-tier treat—no ifs, ands, or buts!

![Doll Authority SEX DOLL 5'2" (157cm) - H-Cup Body Celina Cheap Female Sex Doll - Doll's Castle [USA STOCK]](http://dollauthority.com/cdn/shop/files/doll-authority-sex-doll-celina-cheap-female-sex-doll-doll-s-castle-usa-stock-53249453883737.jpg?v=1714599004&width=533)

![Doll Authority SEX DOLL 5'3" (163cm) - E-Cup Body Cynthia Cheap Female Sex Doll - Doll's Castle [USA STOCK]](http://dollauthority.com/cdn/shop/files/doll-authority-sex-doll-cynthia-cheap-female-sex-doll-doll-s-castle-usa-stock-53250274263385.jpg?v=1719583922&width=533)